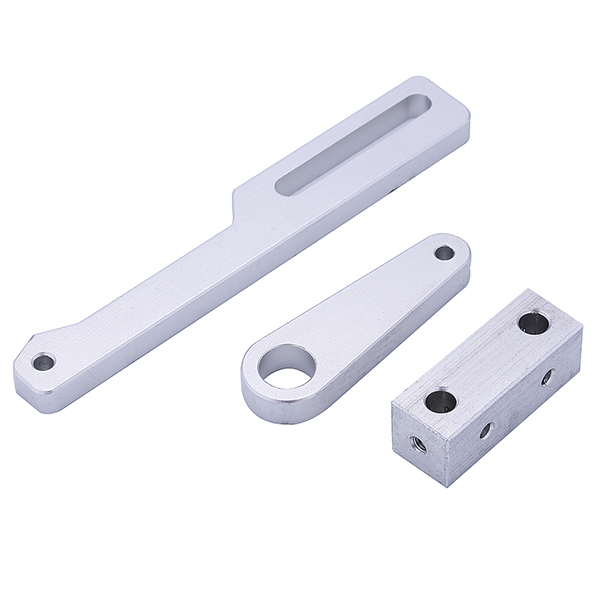

Best Selling CNC Milling Parts Metal Fabrication Component

Processing equipment: CNC Milling machine

Processing method: Rough Milling,Finish Milling,Punching,Tapping,Surface treatment.

Heat treatment: Thermal Refining,Normalizing,Quenching etc.

Surface treatment: Polishing,PVD/CVD coating,Galvanized,Electroplating,spraying,Anodize treatment ,sandblasting, painting and other chemical handings

Application: Car, medical, carrrier,ship,excavator, Automation machine,medical device, industrial machine,automobile, and electric appliance etc.

Drawing format: PRO/E,CAD,Solid works,IGS,UG,CAM,CAE,PDF.

Service: According to customer requirements, provides production design,production and technical service,mold development,and processing to offer one-stop service.

Delivery time: 7-30 days

Packing: EPE foam/Rust proof paper/Stretch film/Plastic bag+carton

MOQ: Negotiable

Advantage

1) 10 years experiences in Precision CNC machining industry

2) Advanced production and testing equipment

3) Strict implementation of international quality standards and management system

4) Mature supplier chain to create value for customers

5) Fast delivery and reasionable price

Measuring Equipment

Projector, CMM, Altimeter, Micrometer, Thread Gages, Calipers, Pin Gauge etc.

Services Provided

CNC milling, CNC turning, drilling, tapping, surface treatment, sand blasting, polishing, wire drawing, silk screen printing, high gloss, anodized, electroplating, painting, assembling and a series of processes make you feel free to receive goods after you place an order!

CNC Turning

CNC lathe Turning is a form of machining, a material removal process, which is used to create rotational parts by cutting away unwanted material. The turning process requires a turning machine or lathe, workpiece, fixture, and cutting tool. We use turning process to manufacture round shape components, such as shafts, pins, bolts, nuts and so on.

CNC Machining

CNC milling

Common machine tools used with CNC machining include mills, routers, grinders, and lathes. ... CNC machines can be used to create metal as well as plastic components. Advantages of CNC Machining. As you can imagine, CNC machining provides a variety of advantages to users as well as the customers to whom they are catering.